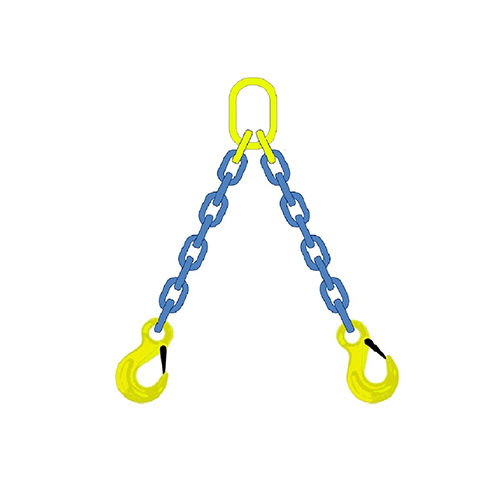

Commercial Weldless Chain Sling

Product Details:

- Usage Industrial

- Condition New

- Feature Corrosion Resistance

- Warranty 1 Year

- Attributes Strong

- Click to view more

Commercial Weldless Chain Sling Price And Quantity

- 1 Piece

Commercial Weldless Chain Sling Product Specifications

- New

- 1 Year

- Strong

- Corrosion Resistance

- Industrial

Commercial Weldless Chain Sling Trade Information

- Cash in Advance (CID)

- 10 Piece Per Month

- 5-7 Days

- All India

Product Description

The Commercial Weldless Chain Sling is meticulously designed to meet the demands of industrial applications. Constructed with superior materials to ensure strong and reliable performance, this chain sling offers exceptional corrosion resistance for long-lasting use, even in challenging environments. Its robust attributes make it ideal for heavy-duty tasks while maintaining a safe and efficient workflow. Suitable for industrial usage, this product is delivered in brand-new condition to guarantee optimal functionality. Backed by a 1-year warranty, it provides peace of mind and assured durability. Perfect for rigorous operations, the Commercial Weldless Chain Sling stands as a dependable tool for professionals seeking quality and resilience in a chain sling.

Chain slings offer years of service and exceptional versatility, as well as immense adjustability. Lift Arts make weldless chain slings are available in many different types, and slings can be sized to fit different lifts by using fittings like chain shorter that allow for adjustment. Weldless chain slings are assembled by using forged mechanical connecting devices like chain connectors etc.

Grade T(8) Alloy Steel Chain is manufactured specifically for use in chain slings for lifting purposes. The chain is heat treated for tensile strength and resistance to wear whilst also allowing for shock absorption.

Chain slings are used primarily for overhead lifting and are generally used in conjunction with a crane or some type of lifting device. Standard sling configurations consist of chain branches, which have master link or ring at top end with some type of attachment, usually a hook, attached to the opposite end. Our Grade T chain slings are recommended for use in an industrial environment where flexibility, strength, resistance and long life are required

Calculated Working Load Limit Uniform Load method of Rating as per IS:15191-2002

| | WLL of Single Leg | Double Branch Slings | Three & Four Branch Slings | ||

| 0 90 0 45 | 90 120 45 60 | 0 90 0 45 | 90 120 45 60 | ||

| Gd-80 | Ton | Ton | Ton | Ton | Ton |

| 6 | 1.1 | 1.5 | 1.1 | 2.3 | 1.6 |

| 7 | 1.5 | 2.1 | 1.5 | 3.1 | 2.2 |

| 8 | 2.0 | 2.8 | 2.0 | 4.2 | 3.0 |

| 10 | 3.2 | 4.4 | 3.2 | 6.7 | 4.8 |

| 12 | 4.6 | 6.4 | 4.6 | 9.6 | 6.9 |

| 13 | 5.4 | 7.5 | 5.4 | 11.3 | 8.1 |

| 14 | 6.3 | 8.8 | 6.3 | 13.2 | 9.4 |

| 16 | 8.0 | 11.2 | 8.0 | 16.8 | 12.0 |

| 18 | 10.0 | 14.0 | 10.0 | 21.0 | 15.0 |

| 20 | 12.5 | 17.5 | 12.5 | 26.2 | 18.6 |

| 22 | 15.5 | 21.7 | 15.5 | 32.5 | 23.2 |

| 25 | 20.0 | 28.0 | 20.0 | 42.0 | 30.0 |

| 28 | 25.0 | 35.0 | 25.0 | 52.5 | 37.5 |

| 32 | 32.0 | 44.8 | 32.0 | 67.2 | 48.0 |

| 36 | 40.0 | 56.0 | 40.0 | 84.0 | 60.0 |

| 40 | 50.0 | 70.0 | 50.0 | 105.0 | 75.0 |

| 45 | 63.0 | 88.2 | 63.0 | 132.2 | 94.5 |

Calculated Working Load Limit Trigonometric method of Rating as per IS:15191-2002

| | WLL of Single Leg | Double Branch Slings | Three & Four Branch Slings | |||||

| =30 =15 | =60 =30 | =90 =45 | =120 =60 | =60 =30 | =90 =45 | =120 =60 | ||

| Gd-80 | Ton | Ton | Ton | Ton | Ton | Ton | Ton | Ton |

| 6 | 1.1 | 2.1 | 1.9 | 1.5 | 1.1 | 2.8 | 2.3 | 1.6 |

| 7 | 1.5 | 2.8 | 2.5 | 2.1 | 1.5 | 3.8 | 3.1 | 2.2 |

| 8 | 2.0 | 3.8 | 3.4 | 2.8 | 2.0 | 5.1 | 4.2 | 3.0 |

| 10 | 3.2 | 6.1 | 5.5 | 4.5 | 3.2 | 8.3 | 6.7 | 4.8 |

| 12 | 4.6 | 8.8 | 7.9 | 6.5 | 4.6 | 11.9 | 9.7 | 6.9 |

| 13 | 5.4 | 10.4 | 9.3 | 7.6 | 5.4 | 14.0 | 11.4 | 8.1 |

| 14 | 6.3 | 12.1 | 10.9 | 8.9 | 6.3 | 16.3 | 13.3 | 9.4 |

| 16 | 8.0 | 15.4 | 13.8 | 11.3 | 8.0 | 20.7 | 16.9 | 12.0 |

| 18 | 10.0 | 19.3 | 17.3 | 14.1 | 10.0 | 28.9 | 21.2 | 15.0 |

| 20 | 12.5 | 21.1 | 21.6 | 17.6 | 12.5 | 32.4 | 24.3 | 18.7 |

| 22 | 15.5 | 29.9 | 26.8 | 21.9 | 15.5 | 40.2 | 32.8 | 23.2 |

| 25 | 20.0 | 38.9 | 34.6 | 28.2 | 20.0 | 51.9 | 42.4 | 30.0 |

| 28 | 25.0 | 48.2 | 43.3 | 35.3 | 25.0 | 64.9 | 53.0 | 37.5 |

| 32 | 32.0 | 61.8 | 55.4 | 45.2 | 32.0 | 83.1 | 67.8 | 48.0 |

| 36 | 40.0 | 77.2 | 69.2 | 56.5 | 40.0 | 103.9 | 84.8 | 60.0 |

| 40 | 50.0 | 96.5 | 86.6 | 70.7 | 50.0 | 129.9 | 106.0 | 75.0 |

| 45 | 63.0 | 121.7 | 109.1 | 89.6 | 63.0 | 163.6 | 133.6 | 94.3 |

FAQs of Commercial Weldless Chain Sling:

Q: What makes the Commercial Weldless Chain Sling suitable for industrial applications?

A: Its strong build and corrosion resistance ensure reliability and durability, even in demanding industrial environments.Q: Is the chain sling delivered in new condition?

A: Yes, the product is supplied in brand-new condition to ensure optimal performance upon utilization.Q: What warranty does the product come with?

A: The Commercial Weldless Chain Sling is backed by a 1-year warranty for buyer assurance.Q: Can this product withstand demanding tasks?

A: Yes, its robust attributes make it ideal for challenging and heavy-duty industrial operations.Q: Does the product resist corrosion effectively?

A: Yes, the chain sling is designed with excellent corrosion resistance to perform consistently in tough conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free