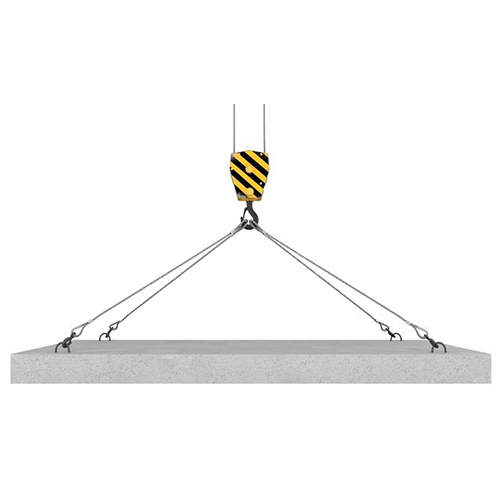

Four Leg Wire Rope Sling

Product Details:

- Grade EN 12385-4

- Wire Gauge 6 mm to 20 mm

- Product Type Four Leg Wire Rope Sling

- Material Steel

- Alloy Carbon Steel

- Strength High Tensile

- Application Lifting, Rigging, Material Handling

- Click to view more

Four Leg Wire Rope Sling Product Specifications

- Carbon Steel

- Natural Steel Grey

- EN 12385-4

- High Tensile

- Steel

- Four Leg Wire Rope Sling

- 6 mm 20 mm

- 6 mm to 20 mm

- Lifting, Rigging, Material Handling

- Customizable Up to 7 Meters

Product Description

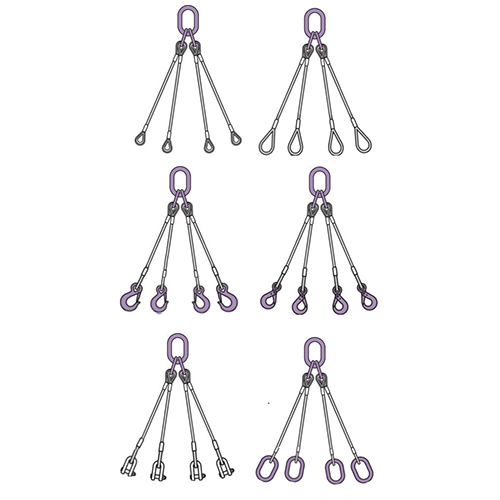

We manufacture Four-legged wire rope slings made of tested quality wire ropes as per IS Specifications with different end fittings attachments for various lifting purpose. We are capable to make these slings as per customers specific requirements of lifting. All slings are as per IS: 2762-1982 and can be supplied in various working load limits (WLL). Splicing of slings are as per IS: 5245 (Part-II). Slings are available with oblong ring and round ring at top.

| Max. Safe Working Load in Kg Four legged Wire Rope Slings | |||

| Min. Rope Size | Permissible WLL of Single Leg | Permissible WLL of 4 Leg Wire Slings | |

| (mm) | (Kg) | At 0 | At 90 |

| 3 | 70 | 210 | 147 |

| 4 | 130 | 390 | 275 |

| 5 | 200 | 600 | 420 |

| 6 | 250 | 750 | 525 |

| 8 | 550 | 1650 | 1155 |

| 9 | 670 | 2010 | 1407 |

| 10 | 800 | 2400 | 1680 |

| 11 | 1000 | 3000 | 2100 |

| 12 | 1200 | 3600 | 2520 |

| 13 | 1400 | 4200 | 2940 |

| 14 | 1750 | 5250 | 3675 |

| 16 | 2000 | 6000 | 4200 |

| 18 | 2500 | 7500 | 5250 |

| 19 | 3000 | 9000 | 6300 |

| 20 | 3300 | 10200 | 7140 |

| 22 | 4000 | 12000 | 8400 |

| 24 | 4600 | 13800 | 9660 |

| 25 | 5000 | 15000 | 10500 |

| 29 | 6500 | 19500 | 13650 |

| 32 | 8000 | 24000 | 16800 |

| 35 | 9200 | 27600 | 19320 |

| 36 | 10400 | 31200 | 21840 |

| 38 | 12000 | 36000 | 25200 |

| 40 | 12700 | 38100 | 26670 |

| 44 | 16700 | 50100 | 35070 |

| 48 | 20000 | 60000 | 42000 |

| 52 | 23000 | 69000 | 48300 |

Superior Construction & Strength

Constructed with 6x19 or 6x36 high-tensile steel wire rope and a steel core (IWRC), this four leg sling ensures maximum durability and load-bearing capacity. Options for galvanized or ungalvanized finishes offer enhanced protection against corrosion, making it suitable for diverse environments.

Safety & Compliance You Can Trust

Engineered with a safety factor of 5:1 and compliant with IS 2762, ISO 7531, and EN 12385-4, this sling prioritizes operator safety and meets rigorous international manufacturing standards. Quality fittings like forged steel hooks or shackles further bolster security in industrial lifting applications.

Versatile & Customizable for Every Project

With wire diameters ranging from 6 mm to 20 mm and lengths up to 7 meters, this sling is ideal for lifting, rigging, and material handling. Customizable specifications ensure a perfect fit for your project requirements, benefiting operations across construction, manufacturing, and logistics.

FAQ's of Four Leg Wire Rope Sling:

Q: How should a Four Leg Wire Rope Sling be used for optimal safety and performance?

A: For safe and effective lifting, ensure each of the four legs is symmetrically loaded and properly attached to the lifting points. Always check that the load does not exceed the maximum 15-ton capacity and that end fittings, such as forged hooks or shackles, are securely fastened. Follow IS 2762 and ISO 7531 guidelines for safe operation.Q: What are the main benefits of using a Four Leg Wire Rope Sling with steel core and high tensile wire?

A: The steel core (IWRC) and high tensile construction provide excellent flexibility, strength, and resistance to deformation. This ensures reliability under heavy loads and durability in rugged industrial environments, reducing maintenance frequency and increasing operational safety.Q: Where can I use a Four Leg Wire Rope Sling like this?

A: This sling is widely used in sectors such as construction, shipbuilding, manufacturing, and logistics for lifting, rigging, and material handling. Its robust design and customizable features make it suitable for various demanding applications both indoors and outdoors.Q: What standards does this sling comply with, and why is compliance important?

A: The sling conforms to IS 2762, ISO 7531, and EN 12385-4 standards, ensuring it meets stringent safety and performance criteria required for industrial lifting equipment. Compliance guarantees consistent quality and protects personnel and assets during operation.Q: When should I choose galvanized over ungalvanized wire rope slings?

A: Galvanized slings should be chosen when your applications expose the sling to outdoor environments or humidity, as the coating offers superior resistance to corrosion. Opt for ungalvanized options in dry, indoor, or less corrosive conditions for cost efficiency.Q: How is the proper wire diameter and sling length determined for my application?

A: The choice depends on the weight and type of load, lift geometry, and headroom available. Wire diameters range from 6 mm to 20 mm, and lengths up to 7 meters can be customized. Consult with your supplier to match the specifications to your precise lifting or rigging requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free