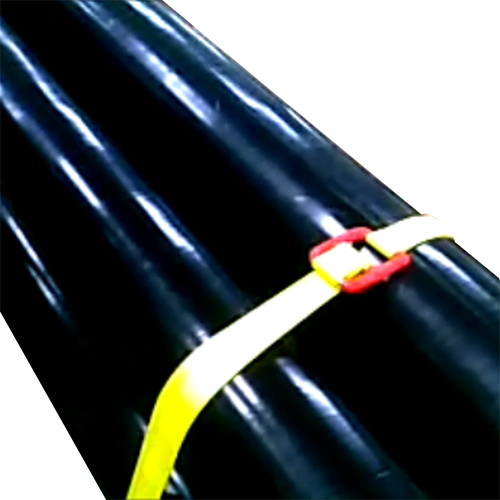

Pipe Bundling Sling

Product Details:

- Forklift Compatible

- Belt Type Polyester Flat Webbing Sling

- Features Wear Resistant, Flexible Handling

- Handle Type Loop Handle

- Lifting Speed Manual

- Control System Manual

- Equipment Type Pipe Bundling Sling

- Click to view more

Pipe Bundling Sling Product Specifications

- Manual

- Easy To Operate

- As per requirement

- Manual

- 2-5 Ton

- Polyester Flat Webbing Sling

- Up to 5 Tons

- Manual

- Pipe Bundling Sling

- Customizable

- Compatible

- Durable, Heavy Duty

- Loop Handle

- New

- Wear Resistant, Flexible Handling

Product Description

The pipes have to be stacked in fixtures/ steel frames so that initial shape is made by the pipes in form of hexagonal bundles. As shown in pictures above single stand or multiple stands near packing/exit area will facilitate the bundling. These frames shall be fabricated considering diameter of pipe and number of pipes in one bundle. For coated pipe the frames should be properly coated /covered by PU Elastomer/ foam/Rubber Sheet or any suitable material to avoid scratches.

Pipe bundling process by DYNAFLEXX

Once pipes have taken their position as a hex shaped bundle, they will be tightened at 5 places by Dynaflex Lashing with minimum 3 ton break capacity which would be more than thrice stronger than conventional steel strap. Lashing is done by a specially provided strainer ratchet.

For coated pipe, buckles will also be coated so that no scratches will be on pipes.

BELOW IS THE PROCESS OF PIPE BUNDLING

Engineered for Heavy-Duty Performance

Constructed from high tenacity polyester, the Pipe Bundling Sling can lift and handle weights up to 5 tons. Its reinforced loops and high safety factor ensure stable and secure lifting, even in challenging industrial environments. Whether used with a forklift or manually, this sling stands out for strength and longevity.

Versatile and Customizable for Every Task

The sling's customizable length and end fittings make it adaptable for different pipe sizes and handling needs. Suitable for both pipe bundling and lifting, its flexible polyester webbing ensures gentle, yet firm handling, reducing the risk of pipe damage. Options for color and packaging add further flexibility for unique requirements.

Designed for Safety and Operator Comfort

Featuring a 6:1 safety factor and resistance to extreme temperatures, chemicals, and wear, this sling prioritizes safety and comfort. The loop handle and manual control system provide ease of operation with minimal risk, ensuring a safe lifting process every time.

FAQ's of Pipe Bundling Sling:

Q: How do I use the Pipe Bundling Sling for lifting pipes safely?

A: To lift pipes safely, ensure the sling is wrapped securely around the bundle with reinforced loop ends attached to the lifting hook or forklift. Check that the load does not exceed the 5-ton capacity and use manual control to lift smoothly. Always follow standard lifting procedures and inspect the sling before use.Q: What are the benefits of using a high tenacity polyester sling for pipe bundling?

A: High tenacity polyester provides excellent strength, durability, and flexibility. It is resistant to chemicals, corrosion, and wear, making it ideal for industrial material handling in harsh environments. The sling's flexible handling minimizes damage to pipes during lifting and transport.Q: When should I choose a polyester flat webbing sling over other materials?

A: Choose a polyester flat webbing sling when you require a lightweight, corrosion-resistant, and easy-to-operate solution that is gentle on loads. It's particularly suitable for handling pipes in environments where moisture, chemicals, or temperature fluctuations are present.Q: Where can the Pipe Bundling Sling be used effectively?

A: This sling is ideal for industrial settings such as construction sites, warehouses, and manufacturing plants where pipe bundling, lifting, and handling are required. Its compatibility with forklifts and manual lifting makes it versatile for various operational needs.Q: What is the process for ordering a customized Pipe Bundling Sling?

A: To order a customized sling, specify requirements such as the desired length, color, lifting capacity, and packaging type. Manufacturers, suppliers, and traders in India offer tailored options to suit your specific application. Ensure to mention lifting load and height requirements during inquiry.Q: Is the Pipe Bundling Sling suitable for handling chemicals or in corrosive environments?

A: Yes, the sling is designed to be resistant to both chemicals and corrosion. It maintains performance and durability even when exposed to harsh substances or damp conditions, making it reliable for diverse industrial uses.Q: What maintenance is required to ensure longevity of the sling?

A: Regularly inspect the sling for signs of wear, cuts, or damage before each use. Clean off any dirt or chemical residue and store the sling in a dry, cool place when not in use. Avoid overloading to maintain its safety factor and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free