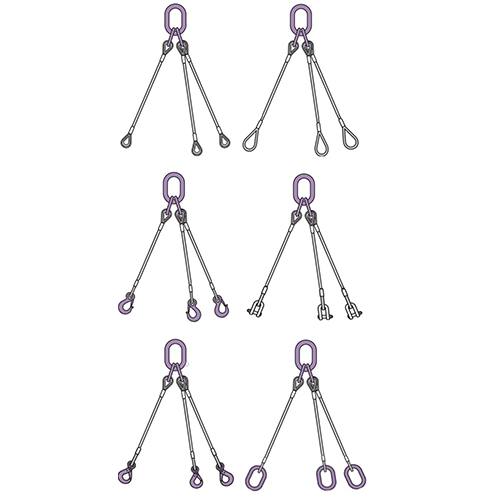

Three Leg Wire Rope Sling

Product Details:

- Wire Gauge 6 mm to 32 mm

- Grade EN 13414-1

- Product Type Three Leg Wire Rope Sling

- Material Steel

- Alloy Carbon Steel / Alloy Steel

- Strength High Tensile

- Application Lifting and Material Handling

- Click to view more

Three Leg Wire Rope Sling Product Specifications

- 6 mm to 32 mm

- Carbon Steel / Alloy Steel

- EN 13414-1

- Natural Metal Finish

- Custom Lengths Available

- Three Leg Wire Rope Sling

- Steel

- 6 mm to 32 mm

- High Tensile

- Lifting and Material Handling

Product Description

We manufacture Three-legged wire rope slings made of tested quality wire ropes as per IS Specifications with different end fittings attachments for various lifting purpose. We are capable to make these slings as per customers specific requirements of lifting. All slings are as per IS: 2762-1982 and can be supplied in various working load limits (WLL). Splicing of slings are as per IS: 5245 (Part-II). Slings are available with oblong ring and round ring at top.

| Max. Safe Working Load in Kg Three legged Wire Rope Slings | |||

| Min. Rope Size | Permissible WLL of Single Leg | Permissible WLL of 3 Leg Wire Slings | |

| (mm) | (Kg) | At 0 | At 90 |

| 3 | 70 | 210 | 147 |

| 4 | 130 | 390 | 275 |

| 5 | 200 | 600 | 420 |

| 6 | 250 | 750 | 525 |

| 8 | 550 | 1650 | 1155 |

| 9 | 670 | 2010 | 1407 |

| 10 | 800 | 2400 | 1680 |

| 11 | 1000 | 3000 | 2100 |

| 12 | 1200 | 3600 | 2520 |

| 13 | 1400 | 4200 | 2940 |

| 14 | 1750 | 5250 | 3675 |

| 16 | 2000 | 6000 | 4200 |

| 18 | 2500 | 7500 | 5250 |

| 19 | 3000 | 9000 | 6300 |

| 20 | 3300 | 10200 | 7140 |

| 22 | 4000 | 12000 | 8400 |

| 24 | 4600 | 13800 | 9660 |

| 25 | 5000 | 15000 | 10500 |

| 29 | 6500 | 19500 | 13650 |

| 32 | 8000 | 24000 | 16800 |

| 35 | 9200 | 27600 | 19320 |

| 36 | 10400 | 31200 | 21840 |

| 38 | 12000 | 36000 | 25200 |

| 40 | 12700 | 38100 | 26670 |

| 44 | 16700 | 50100 | 35070 |

| 48 | 20000 | 60000 | 42000 |

| 52 | 23000 | 69000 | 48300 |

Engineered for Versatility and Strength

The three-leg wire rope sling delivers superior versatility in lifting applications by distributing loads across multiple points. This construction enhances stability and ensures safe usage in varied industrial environments. Manufactured using high-tensile carbon or alloy steel, the slings are available in customizable lengths and wire diameters from 6 mm to 32 mm, catering to a wide range of load requirements and operational needs.

Enhanced Safety and Compliance

Adhering to stringent safety standards such as IS and EN 13414-1, each sling boasts a minimum safety factor of 5:1. This not only reassures performance reliability but also supports regulatory compliance in different industries. The galavanized surface offers excellent corrosion resistance, extending the product's lifespan even in harsh working conditions.

FAQ's of Three Leg Wire Rope Sling:

Q: How is the three-leg wire rope sling utilized in lifting applications?

A: A three-leg wire rope sling is used for balanced, multipoint lifting of heavy loads, where each leg attaches to the load for stable handling. This configuration helps distribute weight effectively, making it suitable for large, asymmetrical, or irregularly shaped objects.Q: What are the benefits of choosing galvanized wire rope slings?

A: Galvanized wire rope slings provide superior corrosion resistance, making them ideal for outdoor or humid environments. This extends the lifespan of the sling, reduces maintenance needs, and ensures safe, long-term operation even in challenging conditions.Q: When should one opt for a fibre core versus a steel core in wire rope slings?

A: Fibre core slings offer greater flexibility and can absorb shock better, which is advantageous for delicate lifting operations. Steel core slings, however, deliver higher strength and temperature resistance, making them more suitable for heavy-duty or high-heat applications.Q: Where can these three-leg wire rope slings be employed?

A: These slings are suitable for various industries, including construction, manufacturing, shipping, and logistics. They are particularly effective in lifting and handling heavy machinery, structural components, and bulk materials in warehouses, ports, or job sites.Q: What compliance standards do these wire rope slings meet?

A: The slings conform to IS and EN 13414-1 standards, and can also be tailored to meet additional customer requirements. This ensures reliable safety, quality, and compatibility with globally recognized norms.Q: How does the surface treatment affect the sling's performance?

A: A galvanized finish enhances corrosion resistance, making the sling ideal for environments exposed to moisture or chemicals. Ungalvanized slings may be chosen for indoor or dry applications where corrosion is less of a concern and might offer greater flexibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+