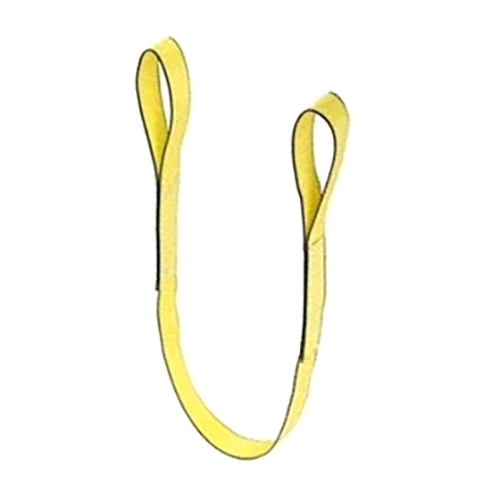

Triplex Sling

Product Details:

- Lifting Speed Manual, depends on user

- Features Triplex Layered, High Load Bearing

- Belt Type Flat Webbing

- Condition New

- Lifting Capacity Variable as per requirement

- Max. Lifting Load Depends on sling specification

- Max. Lifting Height As specified

- Click to view more

Triplex Sling Product Specifications

- Triplex Layered, High Load Bearing

- Custom as per request

- Variable as per requirement

- High tensile strength, Durable, Flexible

- Manual, depends on user

- Manual Operation

- As specified

- New

- Flat Webbing

- Lightweight, Easy handling

- Depends on sling specification

Product Description

FEATURES

- 100% High Tenacity Polyester

- Made of 3 Ply Webbing

- Flat & wide Load bearing surface

- According to EN-1492-1:2000 or ASME B 30.9, IS:15041

- Safety Factor 7:1 and 5:1

- Low Stretch Factor: Elongation 3-7%

- High strength to weight ratio: Weight 80% less than Equivalent Wire or Chain slings

- Available up to 300 mm width & 18 Ton Capacity

- Colour coded for easy identification

- Maximum working temperature 90° c

|

| TRIPLEX WEBBING SLINGS CAPACITY IN KGS | |||||||||||

| WLL in kg with one webbing sling | WLL in kg with two webbing slings | |||||||||||

| Straight lift | Choke Hitch | Basket Hitch up to 7° 7° - 45° 45° -60° 60°Up to 7° | Straight Inclination 7°-45° 45°- 60° | Choke Inclination 7°-45° 45°- 60° | ||||||||

| ITEM CODE | WIDTH | COLOUR CODE |

|

|

|

|

|

| ||||

| MODE FACTOR | M=1.0 | M=0.8 | M=2 | M=1.4 | M=1.0 | M=1.4 | M=1.0 | M=1.12 | M=0.8 | |||

| LTP-1500 | 25 | VIOLET | 1500 | 1200 | 3000 | 2100 | 1500 | 2100 | 1500 | 1680 | 1200 | |

| LTP-3000 | 50 | GREEN | 3000 | 2400 | 6000 | 4200 | 3000 | 4200 | 3000 | 3360 | 2400 | |

| LTP-4500 | 75 | YELLOW | 4500 | 3600 | 9000 | 6300 | 4500 | 6300 | 4500 | 5040 | 3600 | |

| LTP-6000 | 100 | GREY | 6000 | 4800 | 12000 | 8400 | 6000 | 8400 | 6000 | 6720 | 4800 | |

| LTP-7500 | 125 | RED | 7500 | 6000 | 15000 | 10500 | 7500 | 10500 | 7500 | 8400 | 6000 | |

| LTP-9000 | 150 | BROWN | 9000 | 7200 | 18000 | 12600 | 9000 | 12600 | 9000 | 10080 | 7200 | |

| LTP-12000 | 200 | BLUE | 12000 | 9600 | 24000 | 16800 | 12000 | 16800 | 12000 | 13440 | 9600 | |

| LTP-15000 | 250 | ORANGE | 15000 | 12000 | 30000 | 21000 | 15000 | 21000 | 15000 | 16800 | 12000 | |

| LTP-18000 | 300 | ORANGE | 18000 | 14400 | 36000 | 25200 | 18000 | 25200 | 18000 | 20160 | 14400 | |

Reliable Strength and Customization

The Triplex Sling boasts high tensile strength and flexibility, ensuring reliable performance under demanding conditions. Choose between polyester or nylon materials, multiple color options, and custom length to perfectly match your project requirements. Every sling is engineered to meet EN, IS, or specified safety standards, providing peace of mind for lifting and material handling operations.

Versatile Applications Across Industries

This sling is specifically designed for lifting, loading, towing, and material handling in sectors such as construction, warehousing, and shipping. Its lightweight, flat webbing and easy handling make it suitable for both routine and heavy-duty tasks. The triplex layered construction not only increases its load-bearing capacity but also improves its durability and lifespan.

FAQ's of Triplex Sling:

Q: How is the Triplex Sling used in industrial applications?

A: The Triplex Sling is primarily used for lifting, loading, towing, and material handling tasks. It is manually operated and can be attached to cranes or hoists using the specified end fittings, making it suitable for construction, shipping, and warehousing environments.Q: What are the material and safety options available for the Triplex Sling?

A: Customers can choose between polyester and nylon materials, as well as end fittings made of steel or alloy steel. Each sling features a minimum safety factor of 5:1 and adheres to EN, IS, or specified conformity standards, ensuring robust safety and compliance.Q: When should I consider using a Triplex Sling instead of a single or duplex sling?

A: Triplex slings offer enhanced load-bearing capacity due to their triple-layered construction, making them ideal for situations where heavy or bulky loads need to be lifted securely and safely.Q: Where can Triplex Slings be applied most effectively?

A: These slings are highly effective in construction sites, shipping yards, warehouses, and similar environments where lifting and material handling are frequent and require reliable, strong equipment.Q: What is the process for selecting the right Triplex Sling for my requirements?

A: To select the right sling, specify your preferred material (polyester or nylon), color, end fittings, belt length, and required conformity standards. Also determine the maximum lifting height and load, so a customized solution with suitable safety margins can be provided.Q: How does the Triplex Sling benefit daily operations?

A: Its lightweight yet durable construction makes handling and installation easy, while its customizable design caters to a wide range of lifting needs. The flexibility, high tensile strength, and minimal maintenance contribute to increased efficiency and workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free