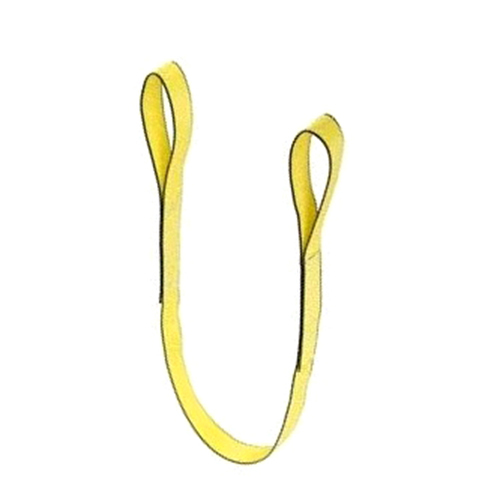

Multiply Polyester Flat Webbing Sling

Product Details:

- Features Abrasion resistant, Wear-resistant, Conforms to EN 1492-1 safety standard

- Control System Manual

- Lifting Speed Manual operation, depends on equipment used

- Belt Type Flat Polyester Webbing

- Equipment Type Flat Webbing Sling

- Condition New

- Lifting Capacity 1 Ton to 20 Tons (Customizable as per requirement)

- Click to view more

Multiply Polyester Flat Webbing Sling Product Specifications

- 1 to 12 meters (Customizable)

- High strength, Durable, Multipurpose, Flexible

- Abrasion resistant, Wear-resistant, Conforms to EN 1492-1 safety standard

- New

- Manual

- Manual operation, depends on equipment used

- 1 Ton to 20 Tons (Customizable as per requirement)

- Lightweight, Non-conductive, Corrosion-resistant, Easy handling

- Flat Webbing Sling

- Manual

- 20 Tons

- Flat Polyester Webbing

- Up to 12 meters, customizable

Product Description

FEATURES

- 100% High Tenacity Polyester

- Made of multi-layered Webbing

- Flat & wide Load bearing surface

- According to EN-1492-1:2000 or ASME B 30.9

- Safety Factor 7:1 and 5:1

- Low Stretch Factor: Elongation 3-7%

- High strength to weight ratio

- Available up to 300 mm width & 110 Ton Capacity

- Colour coded for easy identification

- Maximum working temperature 90°C

|

| FLAT MULTY PLY WEBBING SLINGS CAPACITY IN KGS | ||||||||||

| WLL in kg with one webbing sling | WLL in kg with two webbing slings | ||||||||||

| Straight lift | Choke Hitch | Basket Hitch up to 7° 7° - 45° 45° -60° 60° Up to 7° | Straight Inclination 7°-45° 45°- 60° | Choke Inclination 7°-45° 45°- 60° | |||||||

| ITEM CODE | WIDTH | COLOUR CODE |

|

|

|

|

|

| |||

| MODE FACTOR | M=1.0 | M=0.8 | M=2 | M=1.4 | M=1.0 | M=1.4 | M=1.0 | M=1.12 | M=0.8 | ||

| LMP-36 | 300 | ORANGE | 36000 | 28800 | 72000 | 50400 | 36000 | 50400 | 36000 | 40320 | 28800 |

| LMP-48 | 300 | ORANGE | 48000 | 38400 | 96000 | 67200 | 48000 | 67200 | 48000 | 53760 | 38400 |

| LMP-50-10 | 250 | ORANGE | 50000 | 40000 | 100000 | 70000 | 50000 | 70000 | 50000 | 56000 | 40000 |

| LMP-50 | 300 | ORANGE | 50000 | 40000 | 100000 | 70000 | 50000 | 70000 | 50000 | 56000 | 40000 |

| LMP-60 | 300 | ORANGE | 60000 | 48000 | 120000 | 84000 | 60000 | 84000 | 60000 | 67200 | 48000 |

| LMP-72 | 300 | ORANGE | 72000 | 57600 | 144000 | 100800 | 72000 | 100800 | 72000 | 80640 | 57600 |

| LMP-84 | 300 | ORANGE | 84000 | 67200 | 168000 | 117600 | 84000 | 117600 | 84000 | 94080 | 67200 |

| LMP-100 | 300 | ORANGE | 100000 | 80000 | 200000 | 140000 | 100000 | 140000 | 100000 | 112000 | 80000 |

| LMP-110 | 300 | ORANGE | 110000 | 88000 | 220000 | 154000 | 110000 | 154000 | 110000 | 123200 | 88000 |

Versatile and High-Strength Lifting Solution

Multiply Polyester Flat Webbing Slings offer unmatched flexibility for material handling operations in diverse environments such as construction sites, logistics hubs, and shipyards. These slings support loads from 1 to 20 tons and are customizable in length, ensuring compatibility with a variety of lifting tasks. Their multipurpose design, high strength, and low elongation at working load make them an ideal choice for demanding lifting scenarios requiring both safety and ease of handling.

Premium Material and Superior Construction

Fabricated with 100% high tenacity polyester and available in 2, 3, or 4 plies, these slings exhibit superior resilience against wear, abrasion, and UV light. Reinforced loop or flat eyes and heat-set treatment further enhance durability and longevity, even in harsh conditions. The international color coding system aids in easy sling identification as per lifting capacity, improving operational efficiency and safety on-site.

Safety, Compliance, and Customization

Our webbing slings conform strictly to EN 1492-1 safety standards and offer a choice of safety factors (7:1 or 5:1) according to application needs. With customizable options for ply, length, end fittings, and packaging, you can configure the optimal solution for every unique lifting application. Lightweight and corrosion-resistant, these slings ensure safe manual operations across a broad temperature range without compromising performance.

FAQ's of Multiply Polyester Flat Webbing Sling:

Q: How do I select the correct Multiply Polyester Flat Webbing Sling for my lifting application?

A: To choose the right sling, determine the required lifting capacity, length, and application type. Identify the weight and dimensions of your load and consider environmental factors, then select ply construction (2, 3, or 4 ply) and end fittings that match operational needs. Refer to the international color code for quick capacity identification.Q: What are the main benefits of using a polyester flat webbing sling over steel wire or chain slings?

A: Polyester flat webbing slings are significantly lighter, more flexible, and easier to handle compared to steel wire or chain slings. They are non-conductive, corrosion-resistant, less likely to damage delicate loads, and offer superior abrasion and UV resistance, enhancing operational safety and longevity.Q: When should Multiply Polyester Flat Webbing Slings be inspected or replaced?

A: It is recommended to visually inspect the sling before each use for signs of abrasion, cuts, chemical damage, or other wear. Slings should be replaced immediately if any defects compromising their integrity are found, or as specified by relevant safety guidelines and standards.Q: Where can these slings be used effectively?

A: Multiply Polyester Flat Webbing Slings are suitable for a wide range of environments including construction sites, warehouses, logistics centers, shipyards, and material handling operations, providing a safe and efficient solution for lifting and shifting loads.Q: What is the process for using the sling safely and efficiently?

A: To ensure safe usage, always check the sling's label and color code for capacity, inspect for damage, and select the correct configuration (ply, length, end fitting) for your load. Secure the load with the reinforced or flat eye, lift slowly, and avoid shock loading. Follow manual operation procedures and EN 1492-1 safety standards strictly.Q: Can these slings be customized for unique lifting requirements?

A: Yes, the Multiply Polyester Flat Webbing Sling can be fully customized in terms of lifting capacity (1 to 20 tons), length (1 to 12 meters), ply construction, and end fittings to suit specific material handling tasks and space constraints.Q: What are the care and storage recommendations for extending the sling's working life?

A: Store the sling in a dry, cool area away from direct sunlight and chemicals. Clean the sling after use if necessary, and always ensure it is free from sharp edges during operation. Proper storage and routine inspection will extend the sling's durability and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free