Trusted company that deals in quality-made products

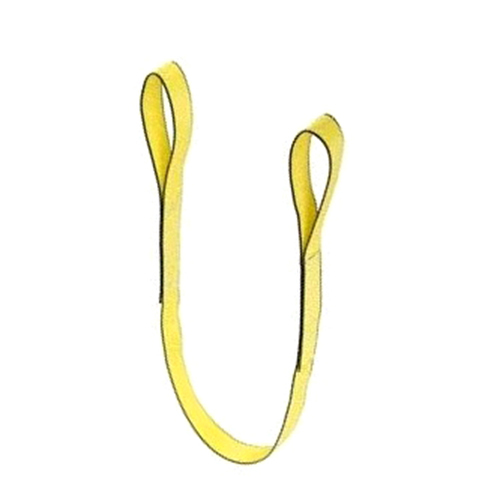

Flat Endless Polyester Flat Webbing Sling

Product Details:

- Features EN 1492-1 Compliant, Color Coded for Capacity

- Control System Manual

- Belt Type Endless Flat Webbing

- Equipment Type Lifting Accessories

- Lifting Speed Manual Operation

- Condition New

- Lifting Capacity 500 kg to 10,000 kg (varies by sling width and ply)

- Click to view more

X

Flat Endless Polyester Flat Webbing Sling Product Specifications

- New

- Depends on sling length

- Endless Flat Webbing

- High Tenacity Polyester Fiber

- Upto 10,000 kg

- EN 1492-1 Compliant, Color Coded for Capacity

- Flexible, Lightweight, Non-corrosive, UV and Abrasion Resistant

- Lifting Accessories

- 1 m to 20 m (customizable)

- 500 kg to 10,000 kg (varies by sling width and ply)

- Manual Operation

- Manual

Product Description

Endless Flat Slings are the most versatile of the entire web sling configuration. Endless Web slings can be used in all 3 types of hitches and perfectly suited for use with traverses in lifting or choking use. The wear points can be adjusted around the circumference of the sling to increase sling life. Compared to eye to eye slings, endless web slings are much simpler to sew and thus are highly economical lifting devices.

FEATURES

- 100% High Tenacity Polyester

- Made of Double thickness of Webbing

- Flat & wide Load bearing surface

- According to EN-1492-1:2000 or ASME B 30.9

- Safety Factor 7:1 and 5:1

- Low Stretch Factor: Elongation 3-7%

- High strength to weight ratio

- Available up to 300 mm width & 12 Ton Capacity in

- Single layer & 24 ton in double layer

- Colour coded for easy identification

- Maximum working temperature 90°C

ADVANTAGES

- Easy handling in choking use.

- Loads are always carried by two strands

- Higher load capacity compare to web slings of equal width.

- Highly cost efficient.

- Ideal for pre-Slung techniques

- Available in simplex or duplex configuration

Color Coded Safety and Standards Compliance

These polyester flat webbing slings strictly follow international color codes, allowing quick visual identification of lifting capacity. Each sling meets the EN 1492-1 standard and provides a safety factor of 7:1, ensuring reliable service even in demanding industrial settings.

Versatile Applications Across Industries

Engineered for general lifting tasks, these slings are ideal for construction, shipping, industrial handling, and on-site applications. The endless loop design allows for flexible use, easily adapting to different lifting configurations and loads.

Durable and User-Friendly Design

Manufactured from high tenacity polyester fiber, these slings are lightweight, flexible, UV resistant, non-corrosive, and abrasion resistant. The reinforced edges and customizable lengths enhance safety and efficiency, making them suitable for rigorous daily use.

FAQ's of Flat Endless Polyester Flat Webbing Sling:

Q: How do I select the correct polyester flat webbing sling for my lifting needs?

A: Choose a sling with a rated lifting capacity suitable for your load, identified by the international color code. Consider factors like load weight, sling width, ply type, and required length for proper configuration and safety compliance.Q: What are the benefits of using a polyester endless flat webbing sling compared to traditional chain or wire rope slings?

A: Polyester webbing slings are much lighter, flexible, and easier to handle. They are non-corrosive, resistant to UV and abrasion, and less likely to damage delicate surfaces, providing greater protection and longevity than traditional alternatives.Q: When should I inspect or replace my flat webbing sling?

A: Slings should be inspected before each use for signs of damage, wear, or cuts. Replace the sling immediately if defects are observed, or as recommended by your safety officer or manufacturer's guidelines to maintain compliance with EN 1492-1 standards.Q: Where can flat endless polyester webbing slings be effectively used?

A: These slings are suitable for various industrial settings such as construction sites, shipyards, factories, and warehouses, providing reliability in lifting, load securing, and material handling applications.Q: What is the process for using an endless loop sling safely?

A: Ensure the sling's rated capacity is not exceeded and check for proper color coding. Secure the sling properly around the load in a choked or basket configuration, avoiding sharp edges that could cause abrasion. Always lift manually unless otherwise specified.Q: How does the color coding system assist in safe operation?

A: Each sling is color-coded according to international standards, representing specific lifting capacities. This makes identification quick and helps prevent overloading or misuse during operations, enhancing safety at the worksite.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free